Salmonella Control

Controlling Salmonella in Dry Pet Food

Prevent salmonella recontamination after extrusion with sodium bisulfate, an ingredient already used in many pet foods.

Pet Food Safety: A Top Priority

Pet foods have been linked to the transmission of pathogenic Salmonella spp. to humans. While various strategies to control Salmonella have led to more vendor inspections, hazard analysis, critical control point (HACCP) plans and hold-and-release programs, every manufacturer is looking for a safety net.

The pet food manufacturing process includes heat lethality steps (the pre-conditioner and extruder) that make the incidence of Salmonella relatively low. However, instances of contamination continue to occur, likely the result of recontamination after the extruder. This recontamination could potentially occur from growth of Salmonella inside the conveying system or possibly from airborne dust in air-handling systems. If either is the case, it is also likely the Salmonella detected are only on the surface of the kibble which could allow a surface-active compound to prove effective.

Multiple Benefits of Acidification with SBS

Research conducted at independent laboratories indicates that sodium bisulfate, the main ingredient in SBS Pet®, has been shown to control Salmonella contamination on the surface of extruded dry pet food. In addition to salmonella control, SBS Pet is already used in pet food for feline urine acidification, pH reduction, and microbial control of soft treats and liquid digest (Aldrich, 2012).

SBS Pet has unique characteristics that make it effective against Salmonella contamination on the kibble surface, including acid strength and a dessicating physically dry state.

Acid strength is denoted by pKa value (Figure 1). The lower the pKa value the stronger the acid. For pH applications below 3.6, less SBS Pet is required to lower pH than most commonly used acids, including phosphoric acid, which reduces cost in pet food, treats, slurry or any low pH application. Sodium bisulfate has one of the lowest pKa’s, at 1.99, of the common acids used in food production.

Acid Strength5 |

|

| Acid | pKa Value |

| Sodium Bisulfate | 1.99 |

| SAPP | 2.10 |

| Phosphoric Acid | 2.16 |

| Citric Acid | 3.14 |

| Acetic Acid | 4.75 |

| Propionic Acid | 4.87 |

Acids that are in a physically dry state have an advantage for Salmonella control as they can be made into a powder that can be dusted onto the kibble without reacting with the surface. Liquid acids will react with the surface components, causing them to be neutralized by proteins and other buffering agents they come into contact with, thus rendering them less effective for Salmonella control.

Research Supported Effectiveness

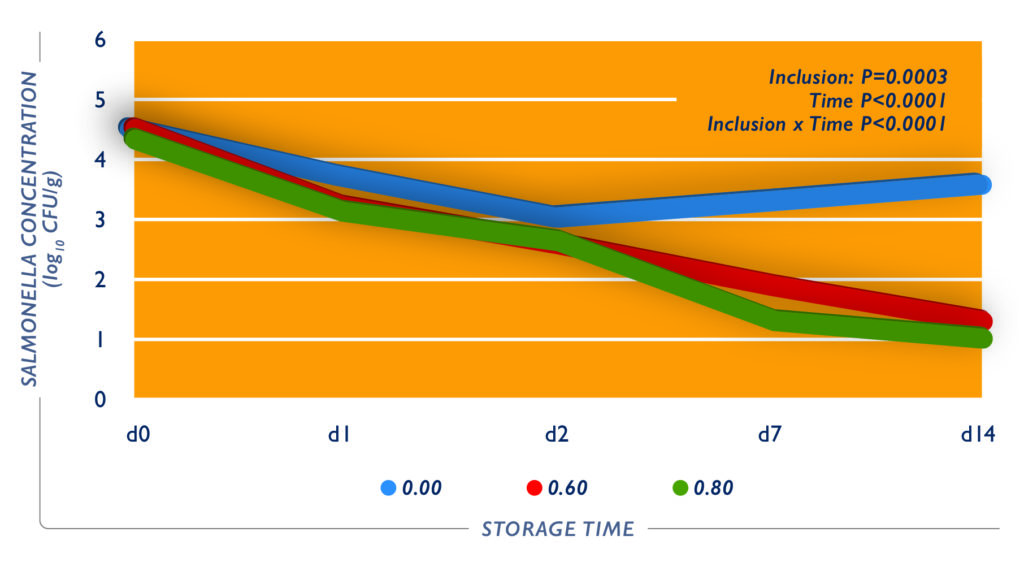

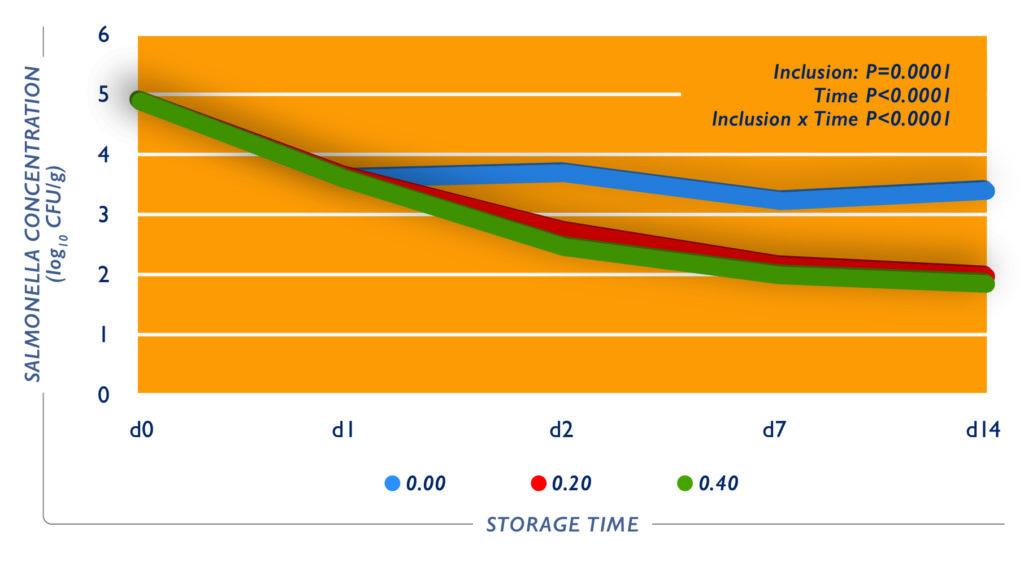

In a study done at Kansas State University, ten different dry, extruded commercial cat and dog foods were inoculated with dry Salmonella enterica at day 0. SBS Pet was applied as a coating at a rate of 0.0, 0.6 and 0.8% to cat food, and 0.0, 0.2 and 0.4% to dog food. Salmonella was then tracked over the course of 14 days.

SBS Pet was shown to reduce Salmonella contamination by one to two logs when applied to dry, extruded pet food (Tables 1 and 2) without affecting palatability.

SBS Pet and Salmonella: The Mode of Action

The mode of action of sodium bisulfate is independent of the type of dry food it is applied to. In its dry form, sodium bisulfate will not react with kibble, allowing it to remain active until consumption.

Sodium bisulfate is an acid salt that, upon contact with water, dissociates into sodium ions, hydrogen ions (which lower the pH) and sulfate ions. It also exerts an osmotic effect, drawing water from the Salmonella, making a low pH environment in contact with the cell. Thus, the critical detail for success is sufficient coverage with sodium bisulfate powder on the entire surface of the food.

Environmental Benefits of SBS Pet

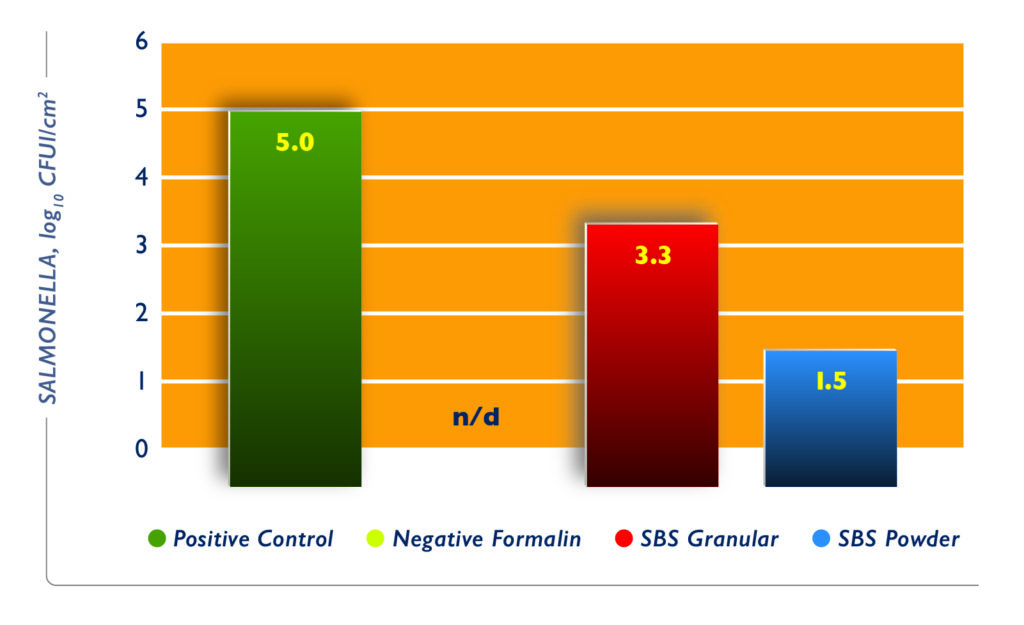

In addition, when used on five different animal food manufacturing surfaces (Plastic, Polyethylene Tote Bag, Rubber, Stainless Steel and Tire) that had been inoculated with 1 mL liquid Salmonella Typhimurium, SBS Pet reduced Salmonella concentration by 1 to 2 logs – the most effective dry product evaluated (Table 3).

Reducing Salmonella in Rendered Fats

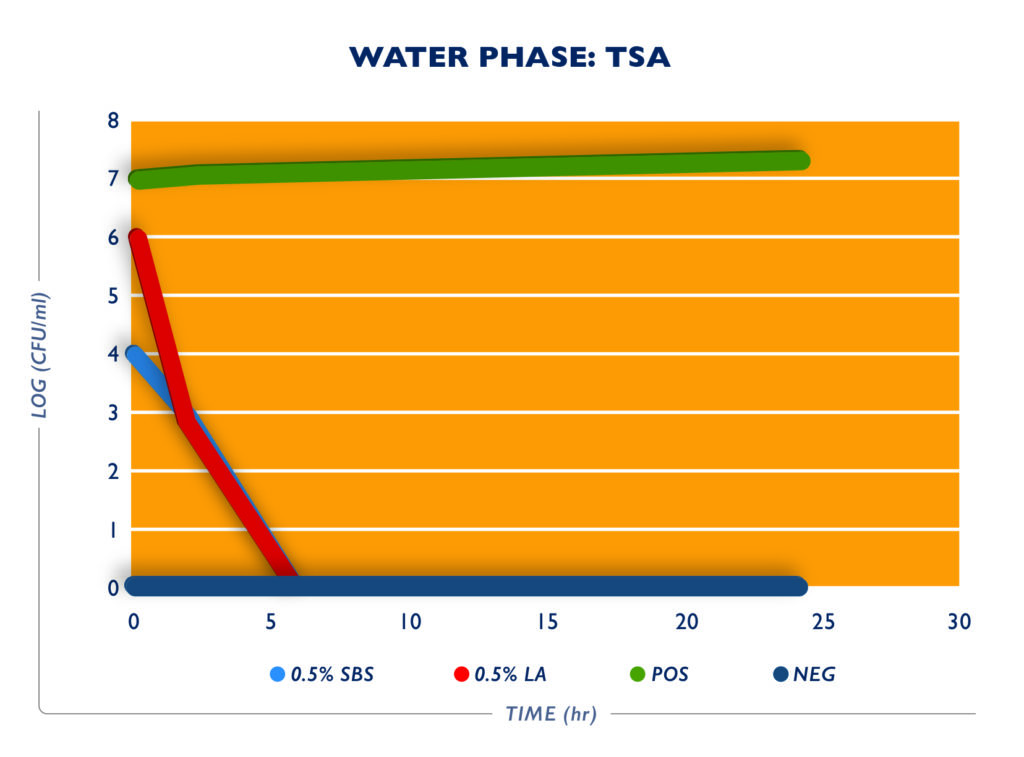

Another potential source of Salmonella contamination is the fat and flavors commonly coated on dry pet foods to increase energy density and enhance palatability. In a separate study done at Kansas State University, researchers found that SBS Pet reduced Salmonella in rendered chicken fat contaminated from the residual water encountered during storage and transport.

Alone SBS Pet was more effective than lactic acid at 0h with a >4 log reduction at 2h and a complete kill for both treatments at 6h (Table 4).

In the fat phase, only a >4 log reduction was detected regardless of treatment, and by 12h Salmonella were not detected in any treatments in the fat phase as it does not support Salmonella growth.